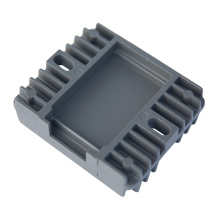

Aluminum A356, Q235 Iron Sand Casting

Product Description

Type: Chemical Hardening Sand Sand Core Type: Resin Sand Core Machining: CNC Machining Surface Treatment: Sand Blast Standard: DIN Sand Casting Mould Frame Material: Aluminum Gravity Casting Frame Material: Ductile Iron,45#Steel Mould Life: 30000pecs Postprocess: CNC Machining Mould Time: 30days Trademark: higer Origin: Hangzhou, Zhejiang Casting Method: Directional Crystallization Application: Furniture Parts Material: Aluminium & Aluminum Alloy Surface Roughness: Ra0.1 Certification: SGS, RoHS, ISO 9001:2008 Die Casting Mould Frame Material: Skt6,Ductile Iron Mould Core: H13 Mould Cavities: According to CAD File Products Tolerance: +/-0.1mm Sample Time: 5days Specification: SGS

Aluminum Casting parts, Aluminum Alloy Casting, Gravity Die Casting, Auto Parts and components, air compressor, housing for power resistors, handles for switching power supplies, clips, Aluminum front panels, terminals, turning parts, fuse holders etc. A Manufacturer of die cast handles. Zinc & aluminum die castings, pneumatic fittings, die cast handles & automotive starter, electrical & tool housings. Die Casting capabilities include tooling, drilling, tapping, facing, slotting & CNC turning. Industries served include electrical, automotive, aircraft, hardware , appliances, architectural, agricultural, communications, telecommunications & government defense.

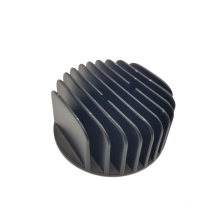

Product Description

1) Aluminum casting guardrail/Aluminum casting chair part/Aluminum Die Casting gardern guardrail

2) Material: Aluminum A380, A356 etc. According to customers' requirement;

3) Product weight from 0.02kg to 5kgs

4) Process: Die Casting + Machining

5) Secondary Machining: CNC turning, milling, drilling, grinding, assembly to packing

6) Surface Finish: Chrome plating, Zinc Plating, Sandblasting, Powder Coating...

7) OEM/ODM parts range: Auto parts, electronic parts, motor shell, Pump Parts , Machinery Parts, light fittings, dental equipment, medical cases etc and other industrial uses

8) Applied software for specification drawings: PRO/E, auto CAD, PDF etc...

9) Products shown on the website are OEM/ODM produced; For reference use on Contact us if you need more details on Sand Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Sand Casting、Aluminum Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Aluminum Casting parts, Aluminum Alloy Casting, Gravity Die Casting, Auto Parts and components, air compressor, housing for power resistors, handles for switching power supplies, clips, Aluminum front panels, terminals, turning parts, fuse holders etc. A Manufacturer of die cast handles. Zinc & aluminum die castings, pneumatic fittings, die cast handles & automotive starter, electrical & tool housings. Die Casting capabilities include tooling, drilling, tapping, facing, slotting & CNC turning. Industries served include electrical, automotive, aircraft, hardware , appliances, architectural, agricultural, communications, telecommunications & government defense.

| Die casting mould | Cavity | Single or multiple |

| Material | H13,DIEVAR,QDN,8407,2344V,TQ1,2343,SKD61, 45#steel,etc. | |

| Heat treatment | Hardened, Nitriding | |

| Hardness | HRC50~55 | |

| Mould features | Advanced design, Logical structure, High precision, Qualified materials, Long lifetime, Short delivery time. | |

| Die casting product | Material | Aluminum alloy,A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3, ADC6, ADC12, ZL104, ZL107. |

| Process | Casting, Deburring, Machining, Surface Treatment, Packing. | |

| Surface treatment | High quality polishing, Chrome/nickek/Zinc(white, blue, yellow, black)plating, hot galvanized, painting, powder coating, Anodizing, electrophoresis, sandblasting and ect. | |

| Leadtime | 7-30 days | |

| Advantage | Company established | in 2003 |

| Software | Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM | |

| Machines | High, refined, sharp equipment, a more high-speed processing center, walking thread cuttings, precision machine sparks, large grinding machines, CNC engraving machines and 10PCS of die-casting machines ( range from 160 to 1250 Tons). | |

| Inspection equipment | Metal material metallographic analyzer, metal detection machine, coordinate measuring machine, large-scale aluminum material direct reading spectrometer, aluminum material hardness meter, X optical testing machine, tensile testing machine, used from mold manufacturing to samples test. | |

| R&D team | Plentiful experience and skillful technique on die casting | |

| Certifications | ISO9001:2008, TS16949 |

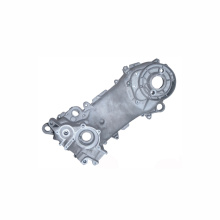

Product Description

1) Aluminum casting guardrail/Aluminum casting chair part/Aluminum Die Casting gardern guardrail

2) Material: Aluminum A380, A356 etc. According to customers' requirement;

3) Product weight from 0.02kg to 5kgs

4) Process: Die Casting + Machining

5) Secondary Machining: CNC turning, milling, drilling, grinding, assembly to packing

6) Surface Finish: Chrome plating, Zinc Plating, Sandblasting, Powder Coating...

7) OEM/ODM parts range: Auto parts, electronic parts, motor shell, Pump Parts , Machinery Parts, light fittings, dental equipment, medical cases etc and other industrial uses

8) Applied software for specification drawings: PRO/E, auto CAD, PDF etc...

9) Products shown on the website are OEM/ODM produced; For reference use on Contact us if you need more details on Sand Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Sand Casting、Aluminum Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Sand Casting Aluminum Part

Premium Related Products

Other Products

Hot Products

Steel CastingZinc Die Casting/Zinc Furniture Part/Zinc PartSteel CastingAluminum PartsDie Casting of Table LegAluminum Die Casting of HousingAluminum Zinc Alloy Die Castings PartsAuto Parts (HG061)Die Casting of Blade Upper Guard of Power ToolDie Casting of Spiral Plate with Textile MachineDie Casting of Base of Street LightingAluminum Advertising BoardDie Casting of Cover of Auto PartsAluminum Die Casting Corner FittingsAluminum Extruded ProfileMold Design