custom casting NiCr alloy radiant tubes for annealing furnace

Product Description

description: casting NiCr alloy radiant tubes for annealing furnace | ||

Materials | NiCr alloy Cr25Ni20 Cr25Ni35 Cr28Ni48W5

| |

Process | lost wax process, soluble glass process , silicon process casting.low pressure casting,forge and so on. | |

Application | stove,annealing furnace,Industrial Furnace | |

Surface treatment | polishing,powder coat,machining center,plating,Heat Treatment,ect. | |

Weight range | 0.02 to 30kg | |

Place of Origin | Shandong, China (Mainland) | |

Standard | DIN,AISI,ASTM,BS,JIS,etc. | |

MOQ | small order is acceptable | |

lead time | 40 days (it depends on the quantity ) | |

loading port | Qingdao,China | |

payment term | TT | |

supply ability | 30000pcs/month | |

packing details | Carton, Iron Pallets,Wooden Pallets, Or as your demand!

| |

Main series of products: the bottom of the furnace roller, roller, radiant tube, tray, basket, mesh belt, chain plate, plate welding pieces, into tube, cracking tube, heat-resistant slide, slide block, walking beam, column, wearing plate, grate plate, screen plate, grate bars, guide roller, guide, and guide assembly and roll ring, nozzle, sintering trolley and GH series high temperature alloy material boat, etc Manufacture Capacity

Main series of products: the bottom of the furnace roller, roller, radiant tube, tray, basket, mesh belt, chain plate, plate welding pieces, into tube, cracking tube, heat-resistant slide, slide block, walking beam, column, wearing plate, grate plate, screen plate, grate bars, guide roller, guide, and guide assembly and roll ring, nozzle, sintering trolley and GH series high temperature alloy material boat, etc Manufacture Capacity

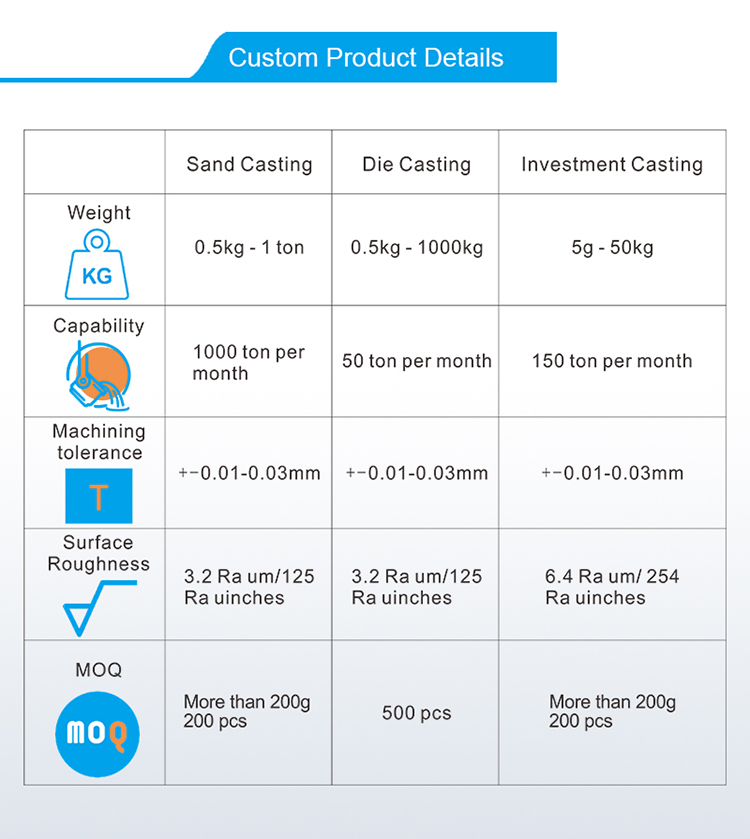

| Item | Description |

| Service | OEM or Sample Production |

| Process Technology | lost wax casting process / soluble glass casting process / silicasol casting process/ Die Casting process /Sand Casting process / + Precision CNC Machining + Surface Treatment |

| Material we can cast | (1)grey iron, ductile iron , pig iron |

| (2)carbon steel, stainless steel, alloy steel | |

| (3)aluminum alloy, aluminium, A380, aluminum 6061 | |

| (4)zinc alloy ,copper, brass, bronze etc | |

| Size | Customized as customer's drawings |

| Surface Treatment | Heat Treatment, Polishing, Plating, Machining, Anodizing, shot, sand blasting, zinc plated, oxide, galvanized etc. |

| Testing | Three coordinate measurement machine for testing. |

| Certification | ISO9001:2015 |

| Standard | ISO , DIN, AISI, ASTM, BS, JIS, etc. |

Application:1. Food Machine hardware Components of liquid food equipment Tapping device for beer, milk and juice dispensers Handles for pot, spoon and fork2. Machine Hardware Safety Locker Quick Coupling Clip Pipe and Fitting Other mechanical hardware3. Pumps&Valves4. Marine Hardware5. Building Hardware6. Mine, Oil, Textile Mechanical Parts Component for mine equipments Component for agricultural and textile machinery Parts for hydraulic and air compressing equipment Contact us if you need more details on Annealing Furnace. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Annealing Furnace Parts、Casting Radiant Tubes. If these products fail to match your need, please contact us and we would like to provide relevant information.

Application:1. Food Machine hardware Components of liquid food equipment Tapping device for beer, milk and juice dispensers Handles for pot, spoon and fork2. Machine Hardware Safety Locker Quick Coupling Clip Pipe and Fitting Other mechanical hardware3. Pumps&Valves4. Marine Hardware5. Building Hardware6. Mine, Oil, Textile Mechanical Parts Component for mine equipments Component for agricultural and textile machinery Parts for hydraulic and air compressing equipment Contact us if you need more details on Annealing Furnace. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Annealing Furnace Parts、Casting Radiant Tubes. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Lost Wax Castings

Premium Related Products